How to Produce Laboratory Glassware: Precision and Science

Laboratory glassware plays a fundamental role in scientific research and experimentation. From beakers and flasks to pipettes and test tubes, these specialized glass tools are essential for conducting precise and controlled experiments. Producing laboratory glassware requires a unique combination of craftsmanship, precision, and scientific understanding. In this article, we will explore the intricate process of how laboratory glassware is manufactured, from raw materials to the finished product.

Raw Materials

The production of laboratory glassware begins with carefully selected raw materials. The primary material used is borosilicate glass, known for its exceptional resistance to heat, chemicals, and thermal shock. This type of glass is essential in laboratory settings where extreme temperatures and chemical reactions frequently occur. Borosilicate glass is composed primarily of silica, boric oxide, and various other compounds to achieve the desired properties.

Melting and Forming

The first step in glassware production is the melting of raw materials. The precise mixture of compounds is heated in a furnace to temperatures exceeding 1500 degrees Celsius. This high heat is necessary to ensure a homogenous molten glass that can be molded into various shapes.

Once the glass reaches the desired consistency, it is ready for forming. There are several techniques for shaping glassware, including:

Blown Glass: This method involves blowing air into a gather of molten glass at the end of a hollow pipe. The glassblower shapes the glass using various tools and molds. This technique is often used for producing items like round-bottom flasks and test tubes.

Pressing: In this method, molten glass is placed into a mold, and pressure is applied to shape it. Pressing is commonly used for manufacturing items with consistent and intricate designs, such as petri dishes.

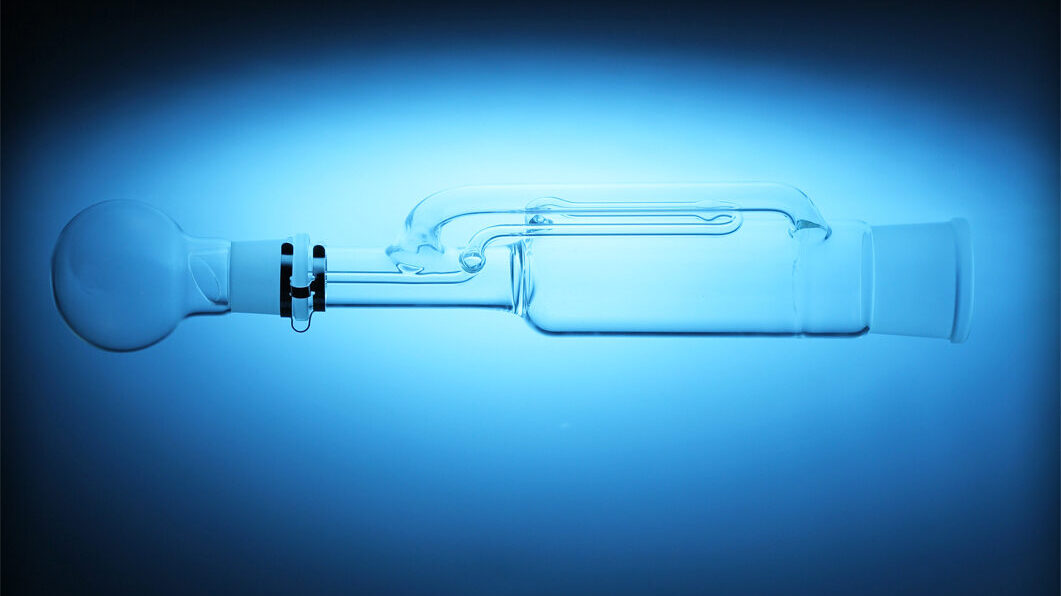

Tubing: Glass tubes are formed by drawing molten glass through a series of dies, creating a continuous tube. These tubes are then cut into specific lengths and used for items like pipettes and condensers.

Sealing: Glass pieces are sealed together by applying heat, creating airtight connections. This technique is used for assembling more complex glassware, such as distillation apparatus.

Annealing

After the glassware is formed, it must undergo an annealing process. Annealing involves slowly cooling the glassware in a controlled manner to relieve internal stresses and ensure uniform thickness. This step is crucial for preventing the glassware from shattering due to thermal stress during use. Proper annealing enhances the durability and safety of laboratory glassware.

Cutting and Finishing

Once the glassware is annealed, it goes through a cutting and finishing process. Glass tubing is precisely cut to the desired lengths, and any sharp edges or imperfections are removed. Additionally, specialized glassworkers may add features such as graduation marks or etched labels to the glassware, improving its functionality and usability.

Quality Control

Quality control is a critical aspect of laboratory glassware production. Each piece is carefully inspected for defects, including bubbles, cracks, or irregularities in shape and thickness. Quality control measures ensure that the glassware meets the high standards required for scientific experiments.

Calibration

Certain types of laboratory glassware, such as volumetric flasks and pipettes, undergo calibration to ensure accuracy. Calibration involves measuring the actual volume of liquid a piece of glassware can hold and marking it accordingly. Precise calibration is essential for obtaining accurate results in scientific experiments and analyses.

Packaging and Distribution

Once laboratory glassware passes quality control and calibration, it is packaged and prepared for distribution. Packaging typically includes protective materials to prevent damage during transit. Glassware is distributed to laboratories, research institutions, educational facilities, and other scientific settings worldwide.

Specialized Glassware

In addition to standard laboratory glassware, there is a demand for specialized glass items designed for specific research applications. For example:

Spectrophotometer cuvettes: These are precision-engineered glass cells used for holding samples in spectrophotometry, allowing the measurement of light absorption or transmission.

NMR tubes: Nuclear Magnetic Resonance (NMR) spectroscopy requires specialized glass tubes to hold samples for analysis. These tubes must be highly transparent and have minimal interference with the NMR signal.

Quartz glassware: Quartz is used for its extreme heat resistance and transparency to UV light. It is employed in applications like UV-visible spectroscopy and chemical reactions at high temperatures.

Conclusion

The production of laboratory glassware is a blend of art, science, and craftsmanship. Starting with carefully chosen raw materials and utilizing precision techniques, glassworkers create essential tools for scientific exploration. The quality, accuracy, and durability of laboratory glassware are paramount in ensuring reliable results in research and experimentation. As technology advances, we can expect further innovations and improvements in the manufacturing of these indispensable tools, supporting the progress of science and discovery in laboratories around the world.

A bejegyzés trackback címe:

Kommentek:

A hozzászólások a vonatkozó jogszabályok értelmében felhasználói tartalomnak minősülnek, értük a szolgáltatás technikai üzemeltetője semmilyen felelősséget nem vállal, azokat nem ellenőrzi. Kifogás esetén forduljon a blog szerkesztőjéhez. Részletek a Felhasználási feltételekben és az adatvédelmi tájékoztatóban.